Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

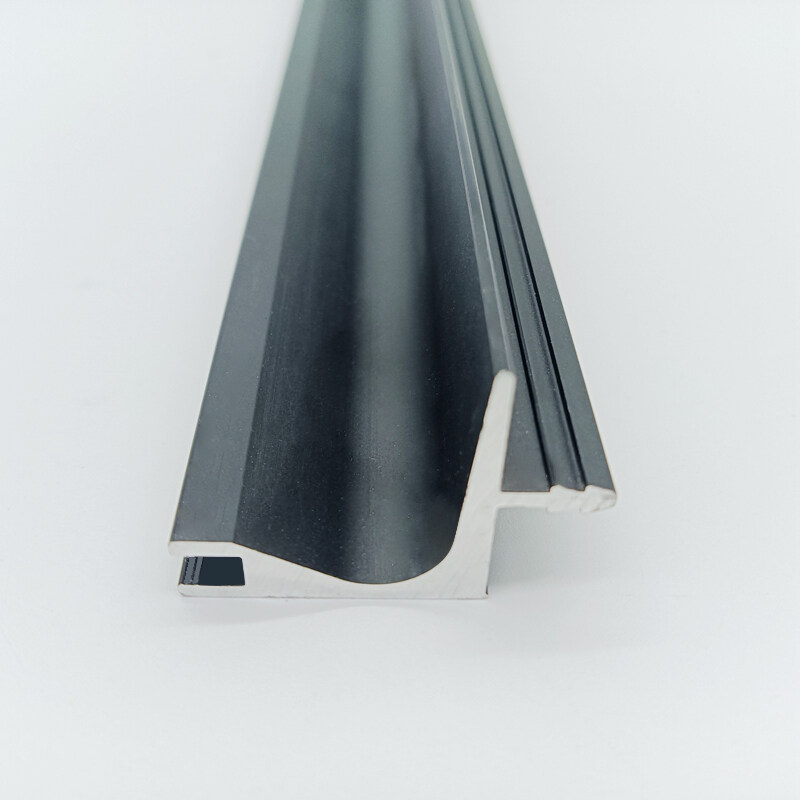

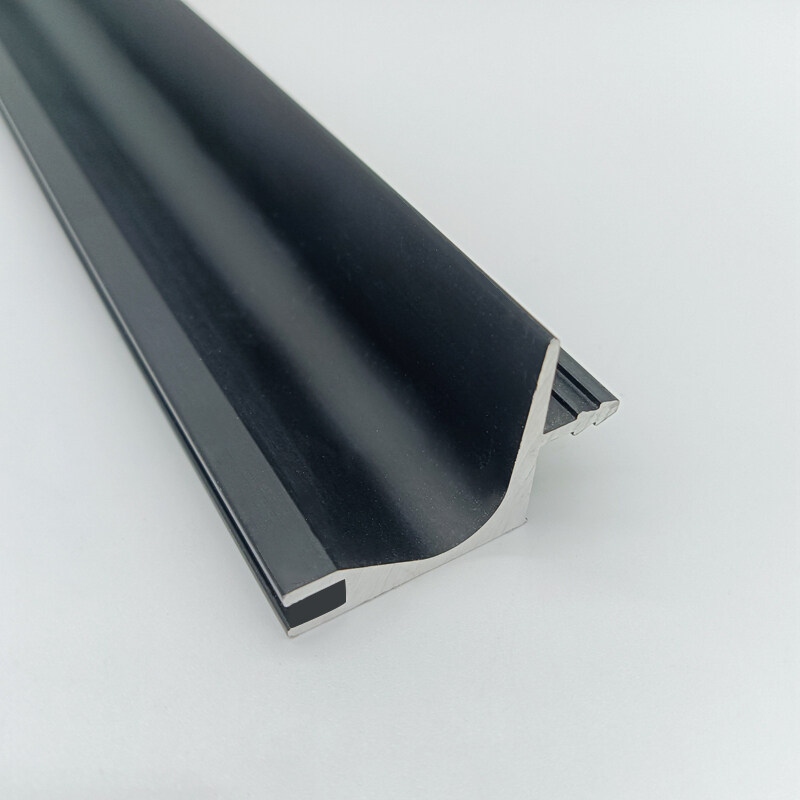

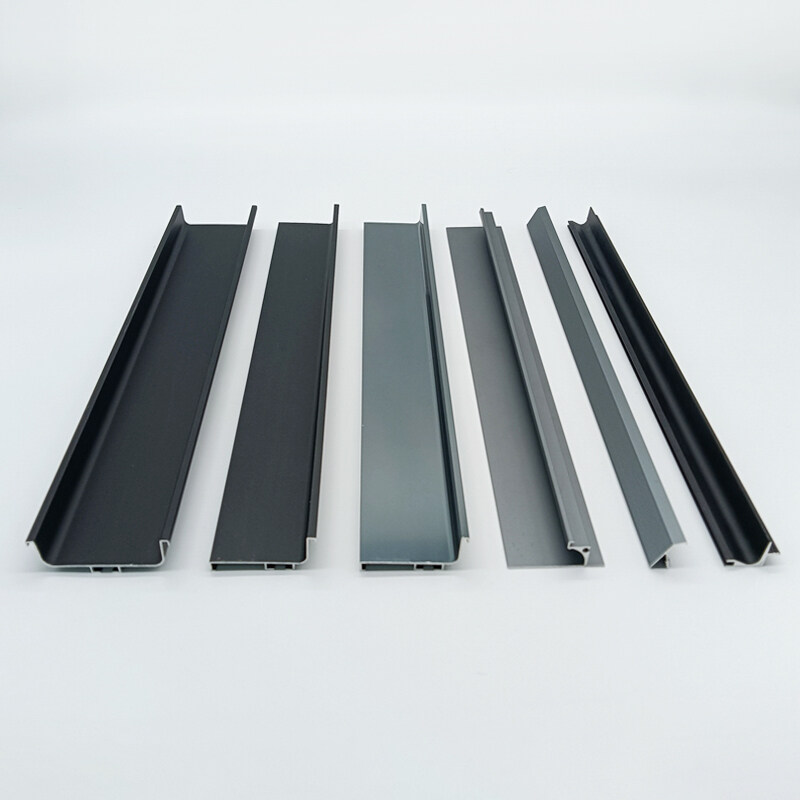

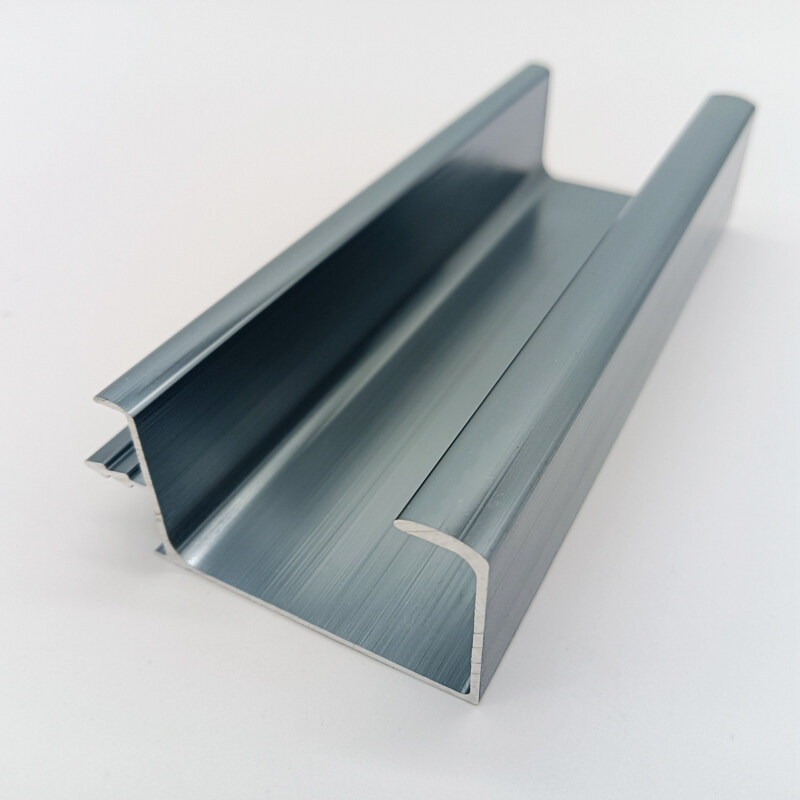

Black cabinet door handle for kitchen Hidden Frame Glass Door Panel Tempered 4 Aluminium Wardrobe Closet Kitchen Cabinet Doors

This set of ergonomically designed handles is a modern and compact solution for modernizing all areas within the house. They are manufactured with high quality aluminum alloy which provides long last durability and a stylish look at the same time.

Product Description: Black Kitchen Cabinet Door Handles

This set of modern and ergonomically designed handles is the ideal solution for modernising all areas of the house. They are manufactured with high-quality aluminium alloy, providing a trendy, modern look and long-lasting durability. Each handle comes with appropriate screws, allowing for a convenient and easy DIY upgrade. This range is suitable for new kitchens and bathrooms, as well as retrofitting existing furniture.

Product Specifications: Black Kitchen Cabinet Door Handles

- Material: Aluminium Alloy

- Design: D-Pull handle

- Finish: matte black

- Handle Dimensions: 137mm x 12mm x 23mm

- Hole Distance: 128mm

- Screw Size: 22mm (suitable for an 18mm board)

Product Features: Black Kitchen Cabinet Door Handles

- Suitable for all types of cabinets, wardrobes, and drawers. Can be installed horizontally or vertically with a hole distance of 128mm.

- Made of top-quality aluminium alloy, it is resistant to rust, fading, and discoloration.

- The multi-layer process creates a protective film that is resistant to corrosion, abrasion, fading, and scratches.

- It is fast and easy to install by simply screwing it on, and it comes with installation screws.

- Contemporary matte black finish, ergonomic design, comfortable grip distance, and easy opening and closing.

Types of Cabinet Handles

- Stainless Steel Handle

Stainless steel handles are widely used in the market and have been in vogue for the past decade. They can be seen on modern cabinet doors or drawers. This flush-pull handle won't get scratched, even if it comes in contact with pants or clothes pockets. The common style of stainless steel handles for cabinets is metal strip handles. The structure of this metal strip handle is that the two ends of the strip are directly connected to the cabinet with screws and fixed. Its design is derived from the modern kitchen construction scheme abroad more than ten years ago, and it is still very popular after years of testing.

- Long Tube Stainless Steel Handle

This is a classic style that has been in fashion for the past decade and is often seen on modern cabinet doors or drawers. It is a flush-pull handle that won't get scratched, even if it comes in contact with pants or clothes pockets.

- Aluminium Alloy Handle

Aluminium alloy cabinet handles are one of the most widely used cabinet door handle materials on the market. The production process employs multi-layer electroplating technology to ensure durability.

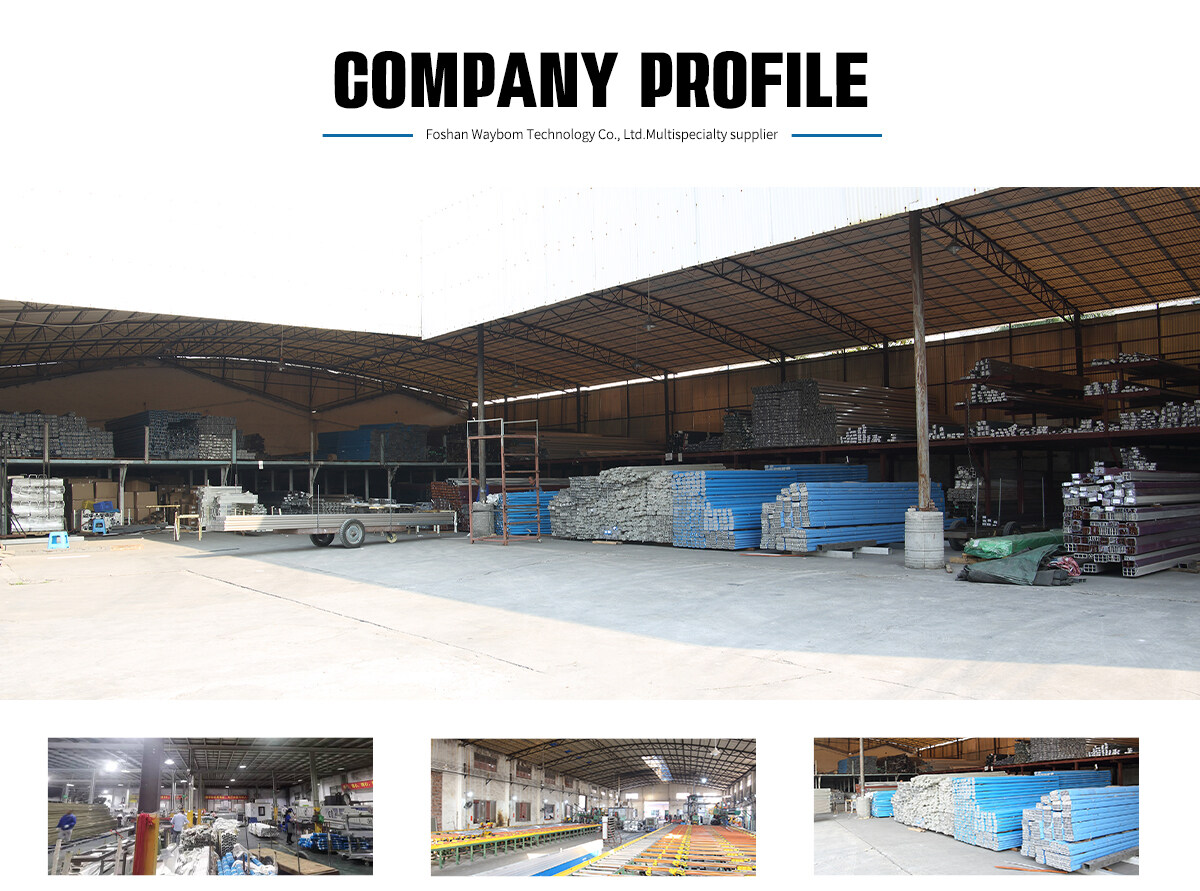

Our factory was established in 2008, covers an area of 56,368 square meters, has 176 employees. With 5 aluminum production lines, 20 CNC machining centers, 2 powder coating lines, several anodizing tanks, Polishing, brushing and sand blasting equipments, Well-established packaging and quality inspection system, our annual output of aluminum is 15000 tons, and more than 20,000 sets of finished products. We can satisfy your demands quickly from our stock or produce your own design. We do ODM and OEM.

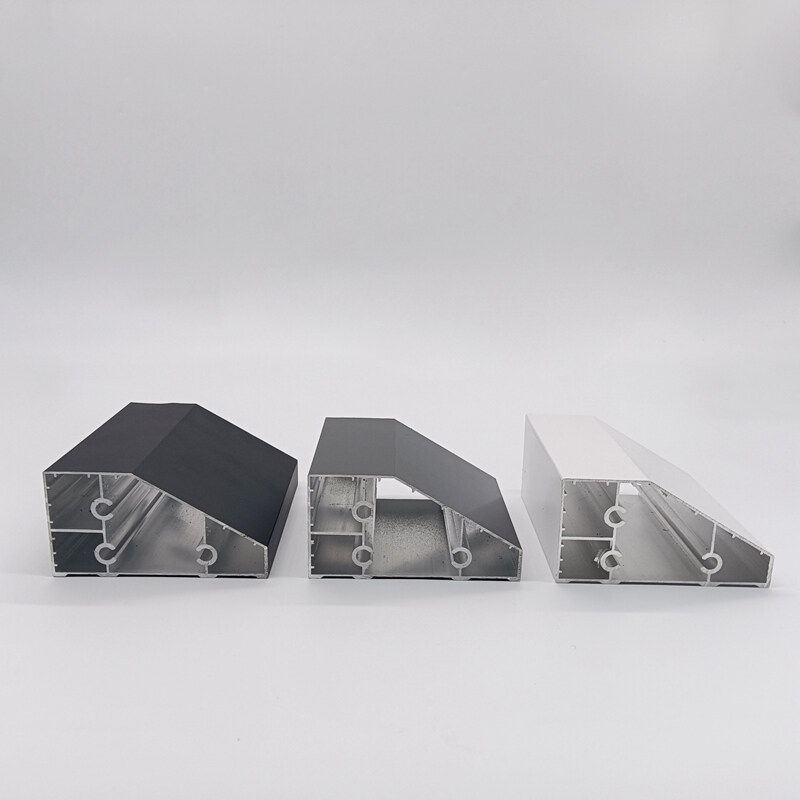

We choose A0 degree aluminum ingot as raw material.

The most used 6063-T5 and 6061-T6 aluminum alloy comply with national standards GB/T5237.

We do extruding with designed moulds to get different shape of profiles.

The strength and toughness of the profiles are ensured by aging treatments.

Surface treatment like powder coating, anodizing and electrophosis are required to protect the profile and get good-looking surface.

We do offer machining services like milling, drilling, bending, threading, etc.

All products will be inspected strictly before packing.

After you place your order, we will check again and suggest you the best packaging method based on different shapes of products (including but not limited to kraft paper packaging/bubble wrap/wooden box packaging).

We provide different packages for different products to make sure the goods can stay good during long-time shipping. And we can do customization according to your requirement.

Usually we will use kraft paper, bubble wrap, plastic protective film, cartons, wood crate and pallet, ect.

Usually we need 15-45 days for production, and we would communicate with customers about all details for shipping a week earlier before goods are ready.

Either you have shipping agents or not, we can assist you to ship the goods and provide you documents for custom clearance. And door to door shipping is also available.